Marine Roller Wheel Rubber Fender

Marine Roller Wheel Rubber Fender Introduction

The Marine Roller Wheel Rubber Fender also called turn cell rubber fender, are generally found in the entrance areas of docks, dry docks, and other narrow or exposed passages. They can be divided into two types – Roller Fenders and Wheel Fenders.

This type of fender is usually installed to guide ships into space-restricted areas like walls of dry docks. Roller Fender has limited energy absorption capacity and is selected mainly due to its ability only to smoothly guide vessels and prevent collision damage.

The Roller Fender is generally built from an energy absorbing elastomer unit which is mounted onto a single rotating shaft. This unit is designed with maintenance-free bearings, typically from stainless steel, and composite material. Mounted into a steel casing it can rotate freely. The main purpose of Roller Fenders is to act as a guiding system for a smooth and safe passage.

There are many design variations for a wheel/roller type fender.

Roller Fenders can be installed in various combinations such as Stacked double or triple fender to cover larger heights in tidal areas, Side by side to guide the vessel through a narrow passage, Installed with an angle to cater for flare angles of the vessel hull

Roller Fenders come in certain standard sizes but typically each project requires a unique design. ShibataFenderTeam would be pleased to receive your design input allowing us to engineer the correct type, size and overall layout of the Roller Fender.

The Marine Roller Wheel Rubber Fender can be supplied with certification from any of the major classification societies.

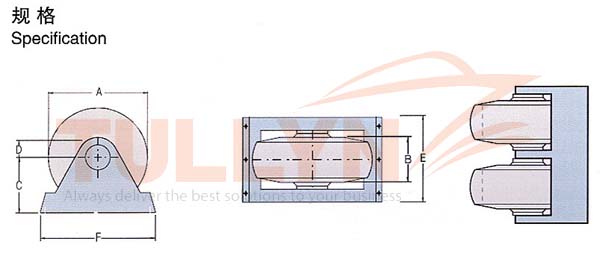

Marine Roller Wheel Rubber Fender Drawing

Marine Roller Wheel Rubber Fender Construction

Marine Roller Wheel Rubber Fender Spec

| Model | A | B | C | D | E | F | G | Weight |

| mm | mm | mm | mm | mm | mm | Rollers | Kg | |

| D1-060-20 | 600 | 200 | 320 | 110 | 420 | 695 | 1 | 120 |

| D1-075-25 | 750 | 250 | 400 | 140 | 510 | 870 | 1 | 230 |

| D1-090-30 | 900 | 300 | 480 | 165 | 610 | 1040 | 1 | 410 |

| D1-120-40 | 1200 | 400 | 640 | 220 | 820 | 1380 | 1 | 980 |

| D1-150-50 | 1500 | 500 | 800 | 275 | 1010 | 1740 | 1 | 1810 |

| D1-180-60 | 1800 | 600 | 960 | 330 | 1210 | 2080 | 1 | 3130 |

| D1-210-70 | 2100 | 700 | 1155 | 385 | 1410 | 2440 | 1 | 4800 |

| D1-240-80 | 2400 | 800 | 1280 | 440 | 1610 | 2770 | 1 | 6040 |

| D2.060-20 | 600 | 200 | 320 | 110 | 770 | 695 | 2 | 210 |

| D2-075-25 | 750 | 250 | 400 | 140 | 935 | 870 | 2 | 420 |

| D2-090-30 | 900 | 300 | 480 | 165 | 1120 | 1040 | 2 | 775 |

| D2-120-40 | 1200 | 400 | 640 | 220 | 1500 | 1380 | 2 | 1770 |

| D2-150-50 | 1500 | 500 | 800 | 275 | 1850 | 1740 | 2 | 3330 |

| D2-180-60 | 1800 | 600 | 960 | 330 | 2215 | 2080 | 2 | 5720 |

| D2-210-70 | 2100 | 700 | 1155 | 385 | 2590 | 2440 | 2 | 9750 |

| D2-240-80 | 2400 | 800 | 1280 | 440 | 2950 | 2770 | 2 | 12400 |

| D3-060-20 | 600 | 200 | 320 | 110 | 1120 | 695 | 3 | 310 |

| D3-075-25 | 750 | 250 | 400 | 140 | 1360 | 870 | 3 | 610 |

| D3-090-30 | 900 | 300 | 480 | 165 | 1630 | 1040 | 3 | 1080 |

| D3-120-40 | 1200 | 400 | 640 | 220 | 2180 | 1380 | 3 | 2550 |

| D3-150-50 | 1500 | 500 | 800 | 275 | 2690 | 1740 | 3 | 4850 |

| D3-180-60 | 1800 | 600 | 960 | 330 | 3220 | 2080 | 3 | 8400 |

| D3-210-70 | 2100 | 700 | 1155 | 385 | 3770 | 2440 | 3 | 13670 |

| D3-240-80 | 2400 | 800 | 1280 | 440 | 4290 | 2770 | 3 | 18390 |

Please note that the above specifications are “general specifications” that pertain to the majority of our production. These specifications should only be used for general, informational purposes. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All specifications are subject to change without prior notice. All pictures shown are for illustration purposes only. Actual product may vary. Classification certification like CCS, DNV, BV, LR, NK, KR, RS shall be provided upon request.

Reviews

There are no reviews yet.