IR Series Centrifugal Hot Liquid Transfer Chemical Pump

IR Series Centrifugal Hot Liquid Transfer Chemical Pump Application

IR Series Hot Liquid Transfer Chemical Pump is a single stage suction, anti-corrosive centrifugal pump, axial suction to transport the corrosive liquid. It is mainly used in papermaking, petroleum, chemistry, pharmacy, etc. IR series pump is made according to the international standard ISO2858 for the design and manufacture according to the international standard ISO5199/DIS, is derived products IH chemical centrifugal pump, the size of the components has been the realization of energy efficient products standard, mainly used in chemical, petroleum, chemical, food, pharmaceutical and other industries transfer freezing point of media solution (or crystallization temperature) high-temperature liquid, corrosive.

IR Series Hot Liquid Transfer Chemical Pump main flow area is provided with a hollow interlayer, and there are available through steam, hot water, hot oil, water and other liquid transport and pump of multi-cycle, heat preservation in a variety of ways and the external insulation system.

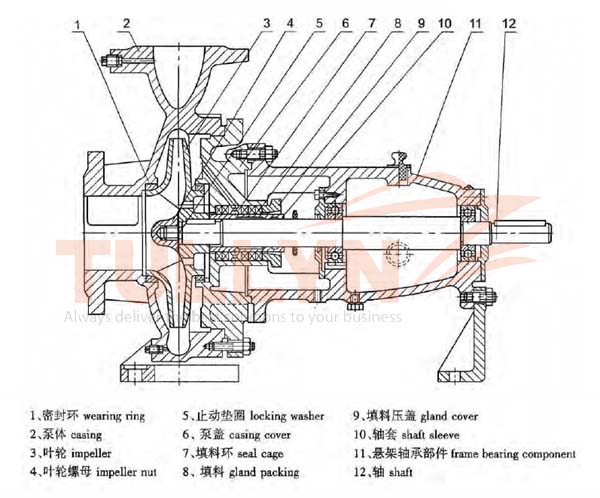

IR Series Centrifugal Hot Liquid Transfer Chemical Pump Drawing

IR Series Centrifugal Hot Liquid Transfer Chemical Pump

IR Series Centrifugal Hot Liquid Transfer Chemical Pump Specification

| Type | Inlet← | Outlet→ | Capacity | Head | Motor Speed |

Motor Power |

Impeller Diameter |

|

| mm | mm | (m³/h) | (m) | r/min | Kw | mm | ||

| IR50-32-125 | 50 | 32 | 12.5 | 20 | 2900 | 2.2 | 125 | |

| IR50-32-125 | 50 | 32 | 6.3 | 5 | 1450 | 0.55 | 125 | |

| IR50-32-160 | 50 | 32 | 12.5 | 32 | 2900 | 3 | 160 | |

| IH50-32-160 | 50 | 32 | 6.3 | 8 | 1450 | 0.55 | 160 | |

| IR50-32-200 | 50 | 32 | 12.5 | 50 | 2900 | 5.5 | 200 | |

| IR50-32-200 | 50 | 32 | 6.3 | 12.5 | 1450 | 0.75 | 200 | |

| IR50-32-250 | 50 | 32 | 12.5 | 80 | 2900 | 11 | 250 | |

| IR50-32-250 | 50 | 32 | 6.3 | 20 | 1450 | 1.5 | 250 | |

| IR65-50-125 | 65 | 50 | 25 | 20 | 2900 | 3 | 125 | |

| IR65-50-125 | 65 | 50 | 12.5 | 5 | 1450 | 0.55 | 125 | |

| IR65-50-160 | 65 | 50 | 25 | 32 | 2900 | 5.5 | 160 | |

| IR65-50-160 | 65 | 50 | 12.5 | 8 | 1450 | 0.75 | 160 | |

| IR65-40-200 | 65 | 40 | 25 | 50 | 2900 | 11 | 200 | |

| IR65-40-200 | 65 | 40 | 12.5 | 12.5 | 1450 | 1.1 | 200 | |

| IR65-40-250 | 65 | 40 | 25 | 80 | 2900 | 15 | 250 | |

| IR65-40-250 | 65 | 40 | 12.5 | 20 | 1450 | 2.2 | 250 | |

| IR65-40-315 | 65 | 40 | 25 | 125 | 2900 | 30 | 315 | |

| IR65-40-315 | 65 | 40 | 12.5 | 32 | 1450 | 4 | 315 | |

| IR80-65-125 | 80 | 65 | 50 | 20 | 2900 | 5.5 | 125 | |

| IR80-65-125 | 80 | 65 | 25 | 5 | 1450 | 0.75 | 125 | |

| IR80-65-160 | 80 | 65 | 50 | 32 | 2900 | 7.5 | 160 | |

| IR80-65-160 | 80 | 65 | 25 | 8 | 1450 | 1.1 | 160 | |

| IR80-50-200 | 80 | 50 | 50 | 50 | 2900 | 15 | 200 | |

| IR80-50-200 | 80 | 50 | 25 | 12.5 | 1450 | 2.2 | 200 | |

| IR80-50-250 | 80 | 50 | 50 | 80 | 2900 | 30 | 250 | |

| IR80-50-250 | 80 | 50 | 25 | 20 | 1450 | 4 | 250 | |

| IR80-50-315 | 80 | 50 | 50 | 125 | 2900 | 45 | 315 | |

| IR80-50-315 | 80 | 50 | 25 | 32 | 1450 | 5.5 | 315 | |

| IR100-80-125 | 100 | 80 | 100 | 20 | 2900 | 11 | 125 | |

| IR100-80-125 | 100 | 80 | 50 | 5 | 1450 | 1.5 | 125 | |

| IR100-80-160 | 100 | 80 | 100 | 32 | 2900 | 15 | 160 | |

| IR100-80-160 | 100 | 80 | 50 | 8 | 1450 | 2.2 | 160 | |

| IR100-65-200 | 100 | 65 | 100 | 50 | 2900 | 30 | 200 | |

| IR100-65-200 | 100 | 65 | 50 | 12.5 | 1450 | 4 | 200 | |

| IR100-65-250 | 100 | 65 | 100 | 80 | 2900 | 45 | 250 | |

| IR100-65-250 | 100 | 65 | 50 | 20 | 1450 | 5.5 | 250 | |

| IR100-65-315 | 100 | 65 | 100 | 125 | 2900 | 75 | 315 | |

| IR100-65-315 | 100 | 65 | 50 | 32 | 1450 | 11 | 315 | |

Please note that the above specifications are “general specifications” that pertain to the majority of our production. These specifications should only be used for general, informational purposes. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All specifications are subject to change without prior notice. All pictures shown are for illustration purposes only. Actual product may vary. Classification certification like CCS, DNV, BV, LR, NK, KR, RS shall be provided upon request.

Reviews

There are no reviews yet.