Type 450 Mining Reeling Cable 3.3 to 33kv

Type 450 Mining Reeling Cable 3.3 to 33kv Application

These type 450 mining cables are suitable for the supply of power to a wide range of applications, from dragline cable to slow reeling applications, where copper screened cable is required but lightweight and smaller dimensions are also desired.

This type 450 cable is a general purpose cable with metal screened power cores with three pilot cores. It is 3.3/3.3 kV to 33/33 kV reeling cables for use with drag-lines, shovels, excavators, wharf cranes, and materials handling equipment. This cable is suitable for slow reeling and trailing applications.

This cable is not suitable for use in underground coal mining applications

Type 450 Mining Reeling Cable 3.3 to 33kv Standard

AS/NZS 2802:2000

AS/NZS 1125

AS/NZS 3808

AS/NZS 5000.1

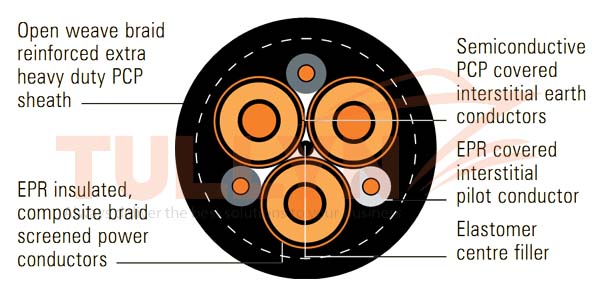

Type 450 Mining Reeling Cable 3.3 to 33kv Construction

Type 450 Mining Reeling Cable 3.3 to 33kv Construction

| 3×Conductors | Flexible stranded tinned annealed copper conductor. |

| Conductor Screen | Semiconductive compound (for cables having a voltage rating of 3.3/3.3kV and above). |

| Insulation | EPR |

| Insulation Screen | Semiconductive elastomer. |

| Composite Screen | Tinned annealed copper braiding interwove with polyester yarn, covered with semiconductive tape. |

| Filler | Elastomer center filler. |

| 2×Interstitial Earth Conductor |

CSP covered flexible stranded tinned copper conductor. |

| 1×Interstitial Pilot | EPR covered flexible stranded tinned copper conductor. |

| Textile Reinforcement | Open-weave braid reinforcement. |

| Sheath | Extra-heavy duty PCP sheath. Extra-heavy-duty CPE/CSP/TPU sheath can be offered upon request. |

Type 450 Mining Reeling Cable 3.3 to 33kv Technical Data

| Voltage Rating | 3.3, 6.6, 11,22, 33kV |

| Operating Conductor Temperature | -25 to 90°C |

| Emergency Conductor Temperature | 130°C |

| Short Circuit Conductor Temperature | Max. 250°C for 5 sec |

| Max. Working Tension | 0.02kN/mm² (total) |

Type 450 Mining Reeling Cable 3.3 to 33kv Specification

Type 450.3 Class 1

| Nominal Conductor Area |

Insulation thickness |

Core Screen Area of each screen |

Pilot/Earth Conductor Thickness of Covering |

Thickness of Sheath |

Nominal Overall Diameter |

Nominal Weight |

| mm2 | mm | mm2 | mm | mm | mm | kg/100m |

| 16 | 2.2 | 6.3 | 1.4 | 4.5 | 42.8 | 266 |

| 25 | 2.2 | 8.3 | 1.4 | 4.8 | 46.9 | 338 |

| 35 | 2.2 | 9 | 1.4 | 5.1 | 50.3 | 392 |

| 50 | 2.4 | 10 | 1.4 | 5.6 | 55.5 | 487 |

| 70 | 2.4 | 14.7 | 1.4 | 6 | 61.1 | 637 |

| 95 | 2.4 | 15.5 | 1.6 | 6.3 | 64.3 | 734 |

| 120 | 2.4 | 17 | 1.6 | 6.4 | 69 | 867 |

| 150 | 2.4 | 18.1 | 1.6 | 6.6 | 73.3 | 1022 |

| 185 | 2.4 | 18.1 | 1.6 | 6.7 | 78.1 | 1175 |

| 240 | 2.4 | 26.7 | 1.6 | 6.9 | 84.5 | 1440 |

| 300 | 2.4 | 28.3 | 1.6 | 7 | 90.4 | 1741 |

Type 450.6 Class 1

| Nominal Conductor Area |

Insulation thickness |

Core Screen Area of each screen |

Pilot/Earth Conductor Thickness of Covering |

Thickness of Sheath |

Nominal Overall Diameter |

Nominal Weight |

| mm2 | mm | mm2 | mm | mm | mm | kg/100m |

| 16 | 3 | 8.3 | 1.4 | 5 | 47.6 | 317 |

| 25 | 3 | 9.1 | 1.6 | 5.2 | 51.2 | 382 |

| 35 | 3 | 9.8 | 1.6 | 5.5 | 54.7 | 443 |

| 50 | 3 | 10.5 | 1.6 | 5.9 | 58.8 | 534 |

| 70 | 3 | 15.5 | 1.6 | 6.3 | 64.3 | 682 |

| 95 | 3 | 16.3 | 1.8 | 6.4 | 67.1 | 771 |

| 120 | 3 | 17.7 | 1.8 | 6.5 | 71.9 | 912 |

| 150 | 3 | 18.1 | 1.8 | 6.6 | 76 | 1073 |

| 185 | 3 | 18.1 | 1.8 | 6.8 | 80.9 | 1222 |

| 240 | 3 | 27.7 | 1.8 | 7 | 87.4 | 1502 |

| 300 | 3 | 28.3 | 1.8 | 7.1 | 93.2 | 1790 |

Type 450.11 Class 1

| Nominal Conductor Area |

Insulation Thickness |

Core Screen Area of each screen |

Pilot Conductor Thickness of Covering |

Thickness of Sheath |

Nominal Overall Diameter |

Nominal Weight |

| mm^2 | mm | mm^2 | mm | mm | mm | kg/100m |

| 25 | 5 | 15.1 | 2 | 6.3 | 62.8 | 542 |

| 35 | 5 | 16 | 2 | 6.4 | 65.8 | 601 |

| 50 | 5 | 17 | 2 | 6.5 | 69.3 | 692 |

| 70 | 5 | 18.1 | 2 | 6.6 | 73.8 | 826 |

| 95 | 5 | 18.1 | 2.2 | 6.7 | 76.6 | 926 |

| 120 | 5 | 18.1 | 2.2 | 6.9 | 81.6 | 1082 |

| 150 | 5 | 27.3 | 2.2 | 7 | 86.1 | 1263 |

| 185 | 5 | 28.3 | 2.2 | 7.1 | 90.8 | 1433 |

| 240 | 5 | 28.3 | 2.2 | 7.3 | 96.8 | 1690 |

| 300 | 5 | 28.3 | 2.2 | 7.4 | 102.7 | 2000 |

Type 450.22 Class 1

| Nominal Conductor Area |

Insulation Thickness |

Core Screen Area of each screen |

Pilot Conductor Thickness of Covering |

Thickness of Sheath |

Nominal Overall Diameter |

Nominal Weight |

| mm^2 | mm | mm^2 | mm | mm | mm | kg/100m |

| 35 | 7.6 | 18.1 | 2.5 | 6.8 | 78.4 | 805 |

| 50 | 7.6 | 18.1 | 2.5 | 6.9 | 81.8 | 900 |

| 70 | 7.6 | 27.5 | 2.5 | 7 | 86.8 | 1070 |

| 95 | 7.6 | 28.3 | 2.5 | 7.2 | 89.8 | 1180 |

| 120 | 7.6 | 28.3 | 2.5 | 7.3 | 94.5 | 1350 |

| 150 | 7.6 | 28.3 | 2.5 | 7.4 | 98.6 | 1520 |

| 185 | 7.6 | 28.3 | 2.5 | 7.5 | 103.4 | 1700 |

| 240 | 7.6 | 28.3 | 2.5 | 7.7 | 109.4 | 1980 |

| 300 | 7.6 | 28.3 | 2.5 | 7.9 | 115.4 | 2310 |

Type 450.33 Class 1

| Nominal Conductor Area |

Insulation Thickness |

Core Screen Area of each screen |

Pilot Conductor Thickness of Covering |

Thickness of Sheath |

Nominal Overall Diameter |

Nominal Weight |

| mm^2 | mm | mm^2 | mm | mm | mm | kg/100m |

| 50 | 10.5 | 28.3 | 2.5 | 7.4 | 96.9 | 1222 |

| 70 | 10.5 | 28.3 | 2.5 | 7.5 | 101.4 | 1385 |

| 95 | 10.5 | 28.3 | 2.5 | 7.7 | 104.4 | 1505 |

| 120 | 10.5 | 28.3 | 2.5 | 7.8 | 109.2 | 1680 |

| 185 | 10.5 | 28.3 | 2.5 | 8 | 118 | 2060 |

| 240 | 10.5 | 28.3 | 2.5 | 8.2 | 124 | 2360 |

| 300 | 10.5 | 28.3 | 2.5 | 8.4 | 130.1 | 2710 |

Please note that the above specifications are “general specifications” that pertain to the majority of our production. These specifications should only be used for general, informational purposes. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All specifications are subject to change without prior notice. All pictures shown are for illustration purposes only. Actual product may vary.

Reviews

There are no reviews yet.